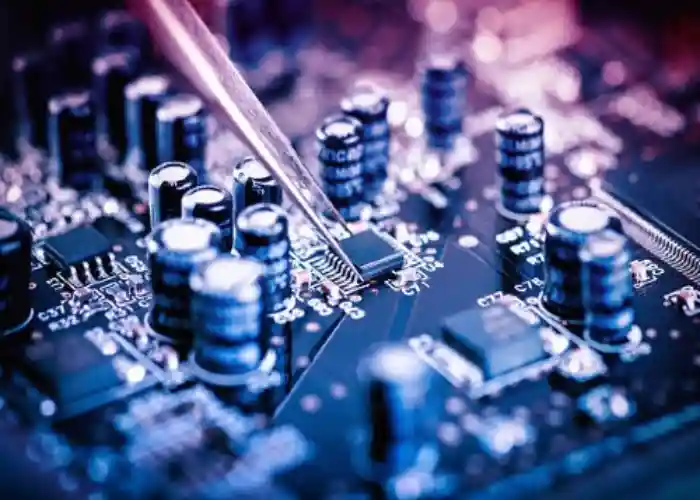

What to Look for in a PCB Assembly Manufacturer?

When selecting a PCB assembly manufacturer, you must be vigilant in evaluating critical aspects that can significantly impact the success of your project. From industry experience to production capacity, each factor plays a pivotal role in determining the manufacturer’s ability to meet your requirements effectively. However, there is one often overlooked aspect that can make or break your experience with a PCB assembly manufacturer. It’s a defining factor that goes beyond technical capabilities and can truly elevate your partnership to the next level.

Industry Experience

With over two decades of experience in the PCB assembly industry, our team at Hitech PCB Assembly Company has honed its skills to deliver high-quality products efficiently. As a reputable PCB assembly manufacturer, we understand the intricate requirements of the industry and have adapted our processes to meet and exceed expectations.

Our wealth of industry experience enables us to tackle complex projects with confidence, ensuring that each product meets the highest standards of quality and reliability. By staying abreast of technological advancements and industry trends, we continuously improve our services to provide our clients with cutting-edge solutions. Trust our seasoned team at Hitech PCB Assembly Company to deliver exceptional results backed by years of industry expertise.

Quality Certifications

Our company holds prestigious quality certifications that validate our commitment to excellence in PCB assembly manufacturing. When selecting a PCB assembly manufacturer, it’s crucial to look for certifications such as ISO 9001, which ensures that our processes meet international quality standards.

Additionally, certifications like IPC-A-610 for printed circuit board assembly demonstrate our adherence to industry-recognized acceptance criteria for electronic assemblies. These quality certifications serve as a testament to our dedication to delivering high-quality PCB assembly services that meet or exceed customer expectations.

Production Capacity

Maximize your understanding of our capabilities by delving into our production capacity. Knowing the production capacity of a PCB assembly manufacturer is crucial for ensuring that your project needs can be met. Our production capacity refers to the volume of PCB assemblies we can manufacture within a specific timeframe.

By evaluating our production capacity, you can determine if we’ve the resources to handle your order size efficiently. Factors such as the number of production lines, equipment capabilities, and workforce play a significant role in determining our production capacity. Understanding this aspect allows you to assess whether our manufacturing capabilities align with your project requirements, ensuring a smooth and timely production process.

Turnaround Time

To ensure your project progresses smoothly, it’s important to understand the turnaround time offered by our PCB assembly manufacturer. Knowing how long it takes for your PCBs to be assembled can help you plan the rest of your project timelines effectively. A quick turnaround time is crucial, especially if you have tight deadlines to meet.

Check with the manufacturer about their production schedules and the average time it takes from placing an order to receiving the final assembled PCBs. Understanding the turnaround time also allows you to anticipate any potential delays and communicate more accurately with your clients or stakeholders. Prioritize manufacturers who can deliver within your desired timeframe without compromising on quality.

Pricing Structure

When considering the pricing structure for your PCB assembly needs, it’s essential to understand the cost breakdown and factors influencing the final price. The pricing model of a PCB assembly manufacturer typically includes costs for components, labor, overhead, and any additional services.

Factors that can affect pricing include the complexity of the PCB design, the size of the production run, and the level of quality control required. Some manufacturers offer volume discounts for larger orders, while others may have minimum order requirements. It’s important to inquire about any hidden fees or charges that may not be initially apparent.

Customer Support

Understanding the level of customer support provided by a PCB assembly manufacturer is key to ensuring a smooth and efficient production process. When evaluating potential manufacturers, consider their responsiveness to inquiries and concerns. A reliable manufacturer should offer clear communication channels, quick response times, and knowledgeable support staff.

Look for a company that values your business and is committed to assisting you throughout the entire assembly process. Effective customer support can make a significant difference in resolving issues promptly, providing technical assistance, and ensuring that your project stays on track. Prioritize manufacturers that prioritize your needs and are willing to go the extra mile to address any questions or challenges that may arise during production.

Conclusion

In conclusion, when selecting a PCB assembly manufacturer, make sure to prioritize industry experience. Quality certifications are also essential, as they ensure the manufacturer adheres to specific standards and guidelines.

Production capacity is another critical factor, as it affects the manufacturer’s ability to meet your production needs. Turnaround time is also crucial, as it directly impacts your product’s time-to-market. Pricing structure is a critical consideration, as it affects your bottom line and profitability.

Finally, customer support is vital, as it ensures the manufacturer is responsive to your needs and provides timely resolution to any issues that arise. By considering these key factors, you can ensure a successful partnership and reliable delivery of high-quality products. Make sure to thoroughly research and evaluate potential manufacturers to make the best choice for your manufacturing needs.