Advantages and Risks of 3D Printing

This manufacturing process is cheaper than traditional manufacturing processes. It can also reduce the costs associated with the materials used and the risk of faulty prototypes. As with any other manufacturing process, this process is not without its risks. Here are some of the most common concerns associated with 3D printing. One of the major concerns is that the process will replace jobs with robots. While there are a number of jobs that will be eliminated, these positions may become redundant if this technology becomes popular enough.

Cheaper than Other Manufacturing Methods

While 3D printing can be costly, the initial cost is much lower than for other manufacturing processes. Unlike other processes, 3D printers don’t require highly skilled machinists or operators. Because of this, the costs of labor for 3D printing are considerably lower than for other manufacturing methods. However, 3D printers can’t produce large quantities for mass production. Therefore, you must consider the size and complexity of the parts before choosing a 3D printing technology, Look at this post.

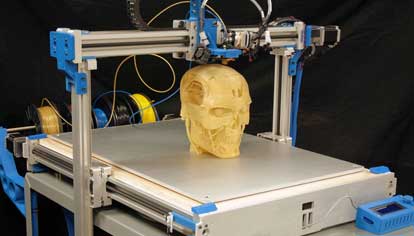

One of the greatest advantages of 3D printing is that you can design and manufacture a part in a matter of hours rather than days. That means that you can quickly design and manufacture a prototype and sell it as you need it. This means that you won’t need to invest in expensive models or proprietary tools. Because 3D printing is cheaper than other manufacturing methods, it will be embraced by many industries. The technology allows companies to save money by avoiding long lead times and high costs of machining prototypes.

Reduces Risk of Faulty Prototypes

In the case of prototyping, the use of 3D printing eliminates many risks. Traditional manufacturing methods such as milling away material and combining ingredients often result in poor quality prototypes. A 3D printer can create parts in layers, ensuring quality and reducing the risk of faulty parts. Furthermore, 3D printing reduces the time needed for testing a prototype. A 3D printed part can be tested within a day, while a traditional manufacturing method can take weeks or even months.

Another benefit of 3D printing is the ability to build physical demonstrations of new products and reduce the risk of miscommunication. This technology allows companies to gain feedback from customers and market test products quickly, without investing a lot of money. Because 3D printers are cost-efficient, the process can be used in various applications, such as prototyping, design considerations, and mass customization. It also offers faster production times, higher accuracy, and more efficient materials.

Reduces Cost of Materials

If you are considering 3D printing, one of the most important considerations is cost. While some materials are much cheaper than others, you must pay attention to how much they cost in general. You may want to start with cheaper materials for testing and prototyping, and then upgrade to higher-quality materials for production. The price per part will also vary greatly depending on the material you choose, but overall, printing materials are cheaper than other processes.

One way to reduce material costs with 3D printing is to modify your model. For example, if you are planning on creating a model that requires supports, you should minimize the overhang. This will save materials by nearly 50 percent. Furthermore, fewer supports will reduce the amount of material you need for post-production. Ultimately, this will save you money on materials and time. However, if you are planning on printing a functional piece, this technique will not work.